Download the model of a castellated beam with circular holes as a surface model here, and open it with the finite element analysis software RFEM. Resistance of the castellated beam. However, previous studies confirm that the method of analysis and design for the solid beam, may not be suitable for the castellated beam. Design guidance on the strength and stiffness for castellated beams is available in most countries, but. The Computer-Aided Design ('CAD') files and all associated content posted to this website are created, uploaded, managed and owned by third party users. Each CAD and any associated text, image or data is in no way sponsored by or affiliated with any company, organization or real-world item, product, or good it may purport to portray.

What is a Castellated Beam?

When it comes to engineering and architecture, there are plenty of things that seem constantly in flux. Every year brings great new ideas and innovations to help today’s thought leaders create the buildings of tomorrow.

However, there is comfort in the idea that certain architectural mainstays are consistent from year to year. For instance, castellated and cellular beams have been in mainstream architectural use for the better part of a century.

And both c-beams, cellular and castellated, show no signs of slowing down anytime soon, as they are still prominently featured in a wide array of modern architecture. We’ve prepared a guide to help you understand the origins, design, and application of c-beams!

General Design

A castellated beam is a beam that has a regular and repeating pattern of hexagonal holes. It is created by cutting the pattern lengthwise across two different halves, offsetting, and then welding them together to create a single expanded beam.

These beams have been used in various construction projects since the second half of the twentieth century. There has also been something of a c-beam renaissance in recent years as engineers have discovered the many versatile uses of these beams in the construction of various construction projects.

C-beams also encompass cellular beams, though the cellular beam fabrication process includes a double-pass process. While cellular beams are more modern and also have many uses, the c-beam is still used for many kinds of construction projects around the world.

History

Before castellated beams, there were i-beams. These were developed way back in 1849 and provided a strong and sturdy way of supporting houses and other structures. Castellated beams were developed as structural channels to increase the beam’s depth and strength without adding additional material and weight.

Since the 1950s, castellated beams have been the ideal construction solution. After World War II, engineers faced steel shortages, and they discovered that these beams were cheap to produce and offered a fantastic strength to weight ratio.

In the 1990s, cellular beams were invented. They eventually replaced many uses for castellated beams, though they are still used for over a fifth of the long-span construction projects in the UK and beyond!

Design Guide 31

One of the reasons that both castellated and cellular beams are prominent once again is Design Guide 31. This is a publication by the American Institute of Steel Construction that provides guidance on best practices in utilizing c-beams for various construction projects. One of these design guides focused on the different uses of castellated and cellular beams.

This design guide wasn’t just created to provide ideas, though. It also provides in-depth information on how architects can fully comply with the 2016 Specification for Structural Steel Building. Before this, architects and engineers alike struggled with how to balance creative uses of these beams with the stringent compliance standards.

Castellated vs. Cellular Beams

While there are many design similarities, there are also some striking differences between castellated and cellular beams. And each kind of beam provides its own unique sets of advantages dependent on your particular construction needs.

The castellated beams are filled with pseudo-hexagonal holes while the cellular beams focus on circular holes. For castellated beams, the holes have size limitations, which means beams may require modification to accommodate larger services. The different hole sizes and fabrication process for cellular beams provide some advantages over the earlier processes.

Cellular beams allow you to change spacing for each beam, allowing you to reduce both the overall number of holes and the amount of infilling you must do. They are also flexible enough to allow various diameters of cell without raising your prices or even changing up your fabrication process.

Cellular beams also allow you to create a range of depths and customize each beam however you see fit, making them ideal for custom projects and unconventional designs.

However, castellated beams still have their own advantages that make many architects and engineers prefer them. For instance, even after all these years, castellated beams offer a desirable weight to strength ratio at a very affordable cost. They have also been the standard for so long that they are easy for any installers and electricians to work with.

C-beams have also become a major part of the architectural aesthetic in America and throughout the world. Using them in construction virtually guarantees that your final building will look classy and elegant to everyone who sees it!

Practical Applications

These c-beams have a number of modern applications. Far from being yesterday’s technology, they still provide the backbone for much of the major architecture you will see in any given city.

One example is parking garages. Major metropolitan areas are facing a grim reality: they have more people coming in every year, but there is not additional space for the growing population. Structures like parking garages have become more important than ever to accommodate drivers within major cities, and c-beams provide significant savings vs. material such as concrete.

Another modern phenomenon is that of the business startup. There are new ideas and new entrepreneurs popping up every day, and this necessitates building more and open air office buildings. C-beams are great for this because it allows architects to get the level of strength they need without having to add materials such as steel. And the flexibility of the c-beams means that you can create as large or small a space as you need with strong, flexible beams that are cheap to buy and simple to use.

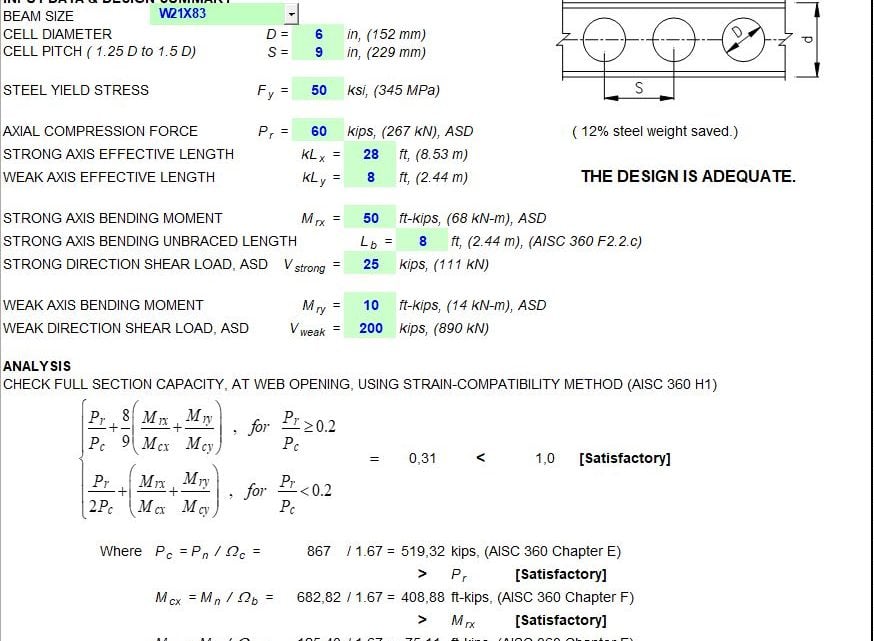

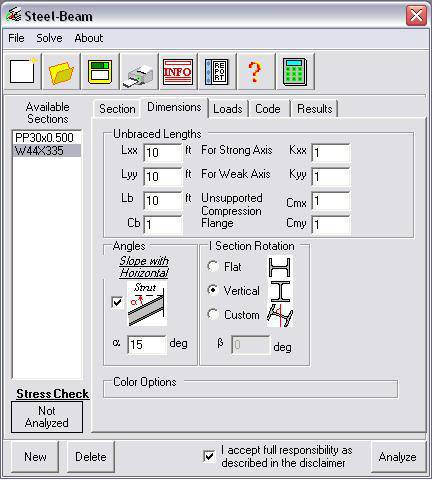

Castellated Beam Design Software Online

Conclusion

As we said, c-beams have been a major component in architectural design since the second half of the twentieth century, and we’re confident they will still be an architectural foundation throughout the entirety of the twenty-first century.

Ultimately, c-beams are exactly what they say on the package. They are light, strong, and cheap, all while providing the simplicity, flexibility, and affordability that engineers demand. When you’ve got big dreams for your future buildings, you’ll definitely want to hold them up with castellated or cellular beams!

Castellated Beam Design Software Reviews

The lightweight appearance of ACB® cellular beams combined with their high strength never ceases to inspire architects in new structural forms. The optimised height/weight or load/weight ratio provides effective answers to the demands of project owners.

This solution allows for large uninterrupted spaces with spans of up to 18 metres and technical installations like pipes and ducts that can pass through the beams' circular web openings.

The purpose of ACB+ is to facilitate the design of cellular beams according to the principles of the Eurocodes.

* ACB: ArcelorMittal Castellated Beams download link provides freeware version of the software.

Predesign of steel and composite castellated beams with sinusoidal openings in normal and fire situation.

ABC: ArcelorMittal Beams Calculator is a free pre-design tool for use in designing a variety of steel and composite structures such as portal frames, beam and column structures, trusses, and column-beam connections.

CoSFB (Composite slim floor beams), a new development by ArcelorMittal, combines the advantages of composite design with traditional slim floor construction and is the perfect answer to the demands of long spans in modern architecture.

ArcelorMittal Construction Phase ACP for composite solutions to check the LTB behaviour of composite and/or partially encased beams during erection.

Compos is a unique composite beam design software program to analyse and design studded composite and non-composite steel beams.

COP is an innovative computer program for the design of joints in steel and composite structures.

No comments yet. Be the first to comment.

Submit a review about ACB: ArcelorMittal Castellated Beams software with your social media profile